News

Welcome to our News page which is updated when we have exciting news to share.

LEVEL 2 COVID19 UPDATE

We are pleased to be operating under Alert Level 2, we will continue to do so as normally as we can in order to protect the gains, we have made in the battle against Covid-19. Along with the rest of the country we are working within the Level 2 restrictions required by the NZ Government.

We are dedicated to delivering the best service possible within these limitations and apologise for any inconvenience they may cause you. During Levels 3 & 4 our customer facing staff and engineers have been working remotely to ensure that as soon as were able to return to work we were ready to work on fulfilling our customers’ orders as promptly as possible.

Before returning to work at our premises all our team have completed a thorough risk assessment to ensure that we are continuing to look after everyone’s well-being.

To increase social distancing in the workplace some office staff are continuing to work from home, or are returning gradually, while the team in the workshop are working on rotating 4 days on 4 days off shifts.

Stafford Engineering trading hours:

Our hours of business remain the same:

Monday – Friday: 7.30am – 4.30pm

Contacting us:

- Our premises are currently operating on restricted access basis with essential visitors only, and strictly by appointment only, however all of the other usual methods of contact are still available http://www.stafford.co.nz/contact-us/

- Before access to site is permitted, all visitors are required to read our visitors notice and complete our Covid-19 Visitor Register along with our health declaration COVID-19-Visitor-Notice-Declaration.pdf . We ask that you do not enter the premises if you are feeling at all unwell.

- All visitors to Stafford Engineering are asked to use the available sanitizer upon entry to our premises.

Dairy upgrade works successfully completed

Dairy upgrade works complete with happy customers. Quality workshop build and site install to meet customers shutdown timeline.

ASME U-Stamp Certification opens US export market to Stafford Engineering

ABS Group story link

Hera story link

Continuous improvement - Can stops reduces downtime

Job done - Happy customer

Customer needed to replace the can handling system on this machine. With some better design and material selection, this line runs smoother and with reduced downtime.

Concept, collaboration, design, manufacture & install. All done to meet the customers shutdown window

Train the Future

A big congratulations to our Apprentices and Cadets at the Gallagher Rotary Awards 2017

The winner and finalist were;

1st Max

2nd Jayden

3rd Oliver

A great effort to all and we are very proud of the SEL commitment towards training our staff for the future.

Here is a short video with Max.

A big welcome to Michelle Roberts - our new Financial Controller at Stafford Engineering.

Michelle is an accountant who studied at Waikato University, has 2 kids and has been involved in the establishment and growth of a contracting business. She enjoys running , Pilates and social Netball. When asked what does she like about working at SEL so far, she replied with “a relaxed culture & team with many new learning opportunities”. Michelle is very keen to contribute in financial management and help grow the business. We wish you all the success.

Congratulations to Phil for 30 years at SEL

We would like to celebrate a great milestone with Phil Jackson reaching 30 years service with Stafford Engineering.

Phil started with SEL on 24th August 1987 when SEL was in Columbo Street Frankton. He has grown with the business through several moves and lots of growth with technology and people. When asked what are some of the things that he has found as highlights during his SEL journey so far, Phil's responses were;

Seeing the technology growth within the business & the ability to grow with it

Good mateship with staff over many years

Seeing people you help train now successfully training others

Sharing & training the youth is satisfying

Congratulations Phil to a job well done & look forward to your continued success.

We are supplying, installing and servicing Rimtec Magnetic Clutches

We are proudly the Aust/NZ agents for Rimtec USA (low inertia) Hysteresis capping clutches which fit onto most aseptic capping lines. These have been developed internationally for high performance low maintenance and keep a low inertia & can be retrofitted to the typical filling lines. These units can be retrofitted to all of the leading filling lines such as Krones, FOGG, KHS, Arol, Shibuya etc…..

Key features

- High quality/ low maint & smooth operation

- Constant torque with varying line speed – which customers need to maintain market acceptable undo cap torque

- Tooless torque adjustment

Certified to provide ASME / PED pressure vessels for global supply

Stafford Engineering is very excited to announce we have added the ability to deliver pressure vessels manufactured in New Zealand that comply to meet ASME & PED pressure vessel certification. This is an additional option to the Australian/New Zealand compliance we already do. We are now supplying a common component to both the USA and European markets. This work is extensive while working with the relevant compliance bodies and meets the customer requirements.

Stafford Engineering will be exhibiting at Auspack in Sydney (stand 84) 7th-10th March 2017

Look at what Stafford Engineering has cooked up

We are proud to have completed a 200L to 1000L Fermentation system. The unit is custom made to suit a flexible process. Thanks to all the staff involved.

Please look at the machine build lifecycle video. https://youtu.be/g9IV5SDSgN8

Stafford Engineering pops in a spout

We are proud to have completed a 30 units per minute spout inserter machine. The unit is custom made to suit the process.Thanks to all the staff involved.

Please look at the machine build lifecycle video. https://youtu.be/lkxP4pQZzHw

Stafford is clutching caps

Stafford Engineering is now the agent for Rimtec Bottle Capping Clutch Technology from the USA for the Australian/New Zealand region. This range of magnetic clutches is built of high quality for high performance capping solutions.

- RCC800 has a special Low Capping Inertia which allows the adjusted torque to be very close to removal torque. This also allows the user to run a different line speed for different size bottles with the same torque setting and still achieve CPK values higher than 1.33.

- 2 year warranty

- Can be Retro-fitted to most filling machines

- The hysteresis magnets disengage very smoothly after tightening the cap.

- Universal design which allows for drop ins on most OEM clutches by putting custom adapters, including adjustable top load, pushing rod and low inertia capping chucks.

- Clutches available with built-in quick chuck connect/disconnect.

- Torque scale is completely linear and almost 360 degrees.

- Torque adjuster is tooless with push down, rotate and lock.

For more information please contact us - details on our website

Stafford Engineering Celebrates 30 years of business

On Saturday 27/8/16 Stafford Engineering staff and their partners happily celebrated 30 years of business with a function held locally in Hamilton.

The function was well enjoyed by all, celebrating this tremendous milestone and great foundation of 30 years of business.

We would like to thank all our customers and dedicated staff for all their contributions.

Our company would also like to thank our company’s founder Roger Evans for his relentless efforts, dedication & leadership over this period. By building a successful company with great people and trusted values that are enjoyed by our staff and customers.

We proudly look forward to building onto our proud 30 year history.

Drop your Boss.... for charity

How many of you would pay money to see our MD Kaleb James thrown off the top of a tall building? https://youtu.be/icegqKryxaU

Well.... we did on Sunday 12/6/16 and proudly raised money to help 2750+ local youth in FYD programs like Kiwi Can, Stars & Career Navigator to be the best they can be.

https://www.linkedin.com/company/stafford-engineering-ltd-/

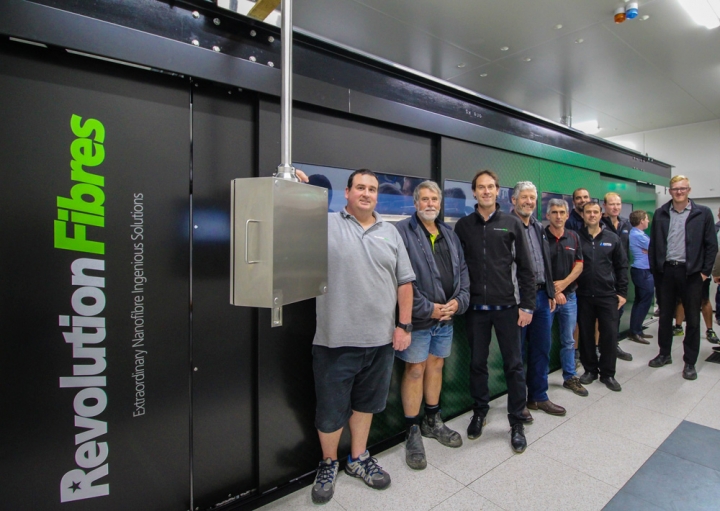

Strand by Strand - Nanofibre drum Machine April 2016

YouTube video - https://youtu.be/74Q3vuyuLts

April 2016 - We are pleased to share one of our current jobs. It’s a Drum Nanofibre machine built for the USA.

It’s our 1st Nanofibre Machine.& the team learnt some of the key technology points. It was a pleasure working with the Revolution Fibres staff.

A professional Stafford Engineering team who delivered on time with a happy customer & a job well done.

The perfect mix up story – the 6000L Mixer

YouTube video - https://youtu.be/QuG7gzZMfMI

Mar 2016 - We are pleased to share one of our current jobs. It’s a 6000 L batch mixer built for the overseas market.

It’s the largest mixer of this type we have manufactured to date. With its shaft made from diameter. 220mm x 6500mm long billet sourced from Sweden & its unique 3 chamber body, the team has enjoyed the challenge.

Handling this size equipment (greater than 8000kg) with precision has been the challenge and all the careful steps in manufacture to ensure the assembly comes together to meet the customers specifications.

A professional Stafford Engineering team who delivered on time with a happy customer & a job well done.

https://www.linkedin.com/company/stafford-engineering-ltd-/

Passing the Baton at Stafford Engineering

May 2015 “Passing the Baton” is a milestone which recognises what has been happening in our business over the last few years. In 2006 I formulated a succession plan that began with Kaleb acquiring shares, later Dave and recently Julian. It’s now time for them to stamp their own mark on our business allowing me to step away from day to day operation, to take up a Governance role. I consider myself very fortunate that Kaleb, now Managing Director, Dave, Sales & Engineering Manager and Julian, Workshop Manager are willing and motivated to take on the challenge and responsibility of ownership and pleased to Pass the Baton to them."

Follow this link: http://www.wbp.net.nz/ebooks/wbn/wbn0615/wbn0615.html#p=1

Looking forward to the next 25 years

Sept 2011 "It has been a 25 year journey so far and while celebrations are in order for reaching such a milestone the Team is looking ahead."

Follow this link www.wbp.net.nz/ebooks/wbn/wbn0911/wbn0911.html and scroll to page 45

Gallagher Rotary Trainee of the Year Awards 2015

Dec 2015 On the night message from Kaleb: "We were pleased to have been invited to participate in the Gallagher rotary industry awards again this year and we continue to see it as great opportunity for our trainees to gain some recognition of the excellence that we expect of them. It's also good for us to promote some friendly competition amongst our current trainees so that they continue to strive to exceed expectations through the course of their training and into their future careers. Currently we have 9 employees in various training agreements with us, 7 of these are in apprenticeships and 2 in our cadet programme working towards a National Diploma in Engineering with study completed here at Wintec. There is good spread of skill level throughout these 9 guys from Light Fabrication to Fitting & Machining and General Engineering with 2 of the apprentices very close to gaining their trade qualification. So with 2 coming out we’re looking again to continue with our commitment to industry training and while this may sound like quite an undertaking we feel that it is industries responsibility to ensure that there are skilled trade’s people available to continue in the future engineering sector. The challenges we face as a business will continue to change and with a great team of skilled people we can prepare ourselves to adapt and be flexible so we continue succeeding in the future. Technology will certainly be one of those challenges and having smart young people who have inherent skill and knowledge in this area allows new thinking, given the opportunity to grow, and develop through coaching, mentoring and the odd push here and there I’m sure all these guys are capable of seizing that opportunity and making the most of it. Now I’d like to introduce each of our finalists for this year Hayden – Is just about to complete his apprenticeship his fitting & machining apprenticeship and has really stepped up in the last 6 – 9 months and also matured as an individual. He’s become very flexible with the ability to run a couple of our key machines, a very large machining centre and also any of CNC lathes. The quality of work he produces is also of a very high standard and I hope to continue watching his skills develop as he progresses into the next stage of his career. Oliver – Is the new kid on the block and is coming to the end of his first year in our cadet programme studying towards completing the NZ diploma in engineering here at Wintec whilst working part time for us. When I first met Oliver his enthusiasm for engineering and his thirst for knowledge really impressed me and I’m still not sure how far he will take himself. If I was a betting man I’d certainly be putting money on it being a very long way. I have big hopes & expectations for what this young man will achieve over the next few years as the potential is definitely bubbling over. Chris – Unfortunately could not be with us tonight but started with us as a trade’s assistant back in May 2011 with the hope of gaining a light fabrication apprenticeship. He spent quite a bit of his time initially setting and operating our laser cutter and he’s had to work hard to convince us that he’s worth a shot as a fabricator. He’s now very close to completion and it may seem like it’s been a long road for him but he’s certainly come of age recently with high quality workmanship and a no fuss demeanour that ensures positive communication and relationships with other members of his team and a level of trust and respect from his peers to do the right things right. Josh – Is taking a bit of a different career path to the others as he came to us having completed study for his NZ diploma in engineering here at Wintec and is now working towards obtaining his NZDEP with the idea with this qualification blends the practical hands on component of engineering with the theory that sits behind it. Josh has recently successfully completed a good project with a lot of learning in this area. He was heavily involved in the assembly site install and commissioning of a pallet conveyor system that was handling beehives and did a good job of his component of this project and was highly commended by his peers for the role he took in getting it across the line. Supporting these guys through their training programs I’d especially like to thank Julian, James & Grant who as part of the workshop management team have the greatest influence on the progress of our apprentices along the way. I would also like to thank John at Competenz for the support that he gives them, keeping them honest and ensuring that unit standards are completed and that they are progressing through their apprenticeships as required. Finally I would like to announce the award for the 2015 Stafford Engineering trainee of the year which this year I’m pleased to present to Hayden Stuart. Like I said before Hayden has really stepped up in the last 6 – 9 months and this has made him the pick of the bunch tonight. Congratulations Hayden, well done!"